Screens

High Sieving Capacity with Low Overall Height

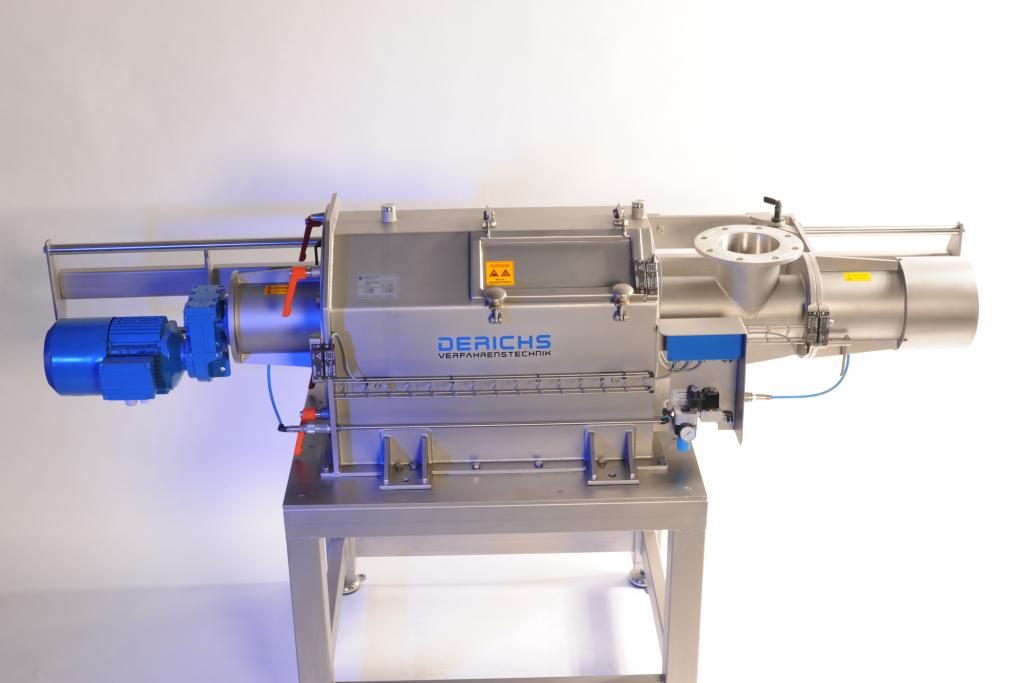

The Centrifugal Sifter TSW has been successfully used in the food and chemical industry for many years. The centrifugal sifter machine is available in three sizes, whereby the sieving capacity is dependent on the product properties and the screen basket mesh width. Even at low height, high performance is achieved!

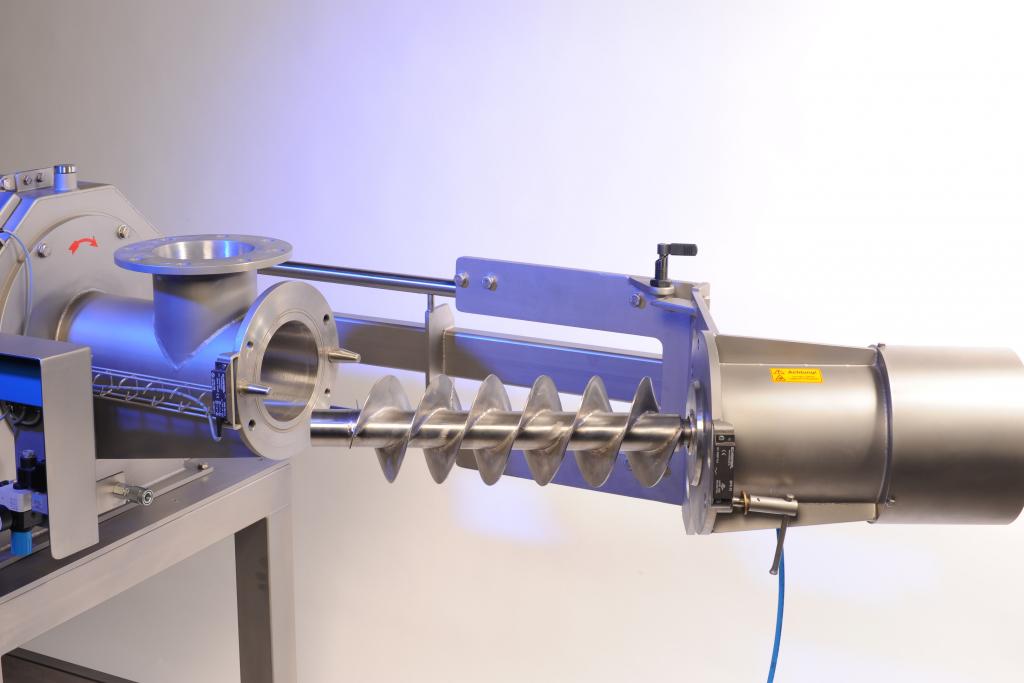

A short feeding screw feeds the product from the inlet into the screening chamber. There it is detected by the swirlists and thrown against or through the cylindrically arranged screen. The coarse material is then transported to the coarse material discharge.

The Centrifugal Sifter TSW can improve and monitor product quality in the following areas:

Control screening: Excretion of foreign particles such as bag fibers, strips of paper bags and screws, etc. which may be present in the product.

Dissolving or separating lumps: Products stored in bags, big bags or containers may tend to form clumps. These lumps are dissolved or excreted in the screening machine.

Dissolving products: In the industrial bakery, the flour is enriched with air through the centrifugal sifter before it enters the kneader. This increases the yield.

Fractionating: Sieving of product fractions which exceed a certain grain size.

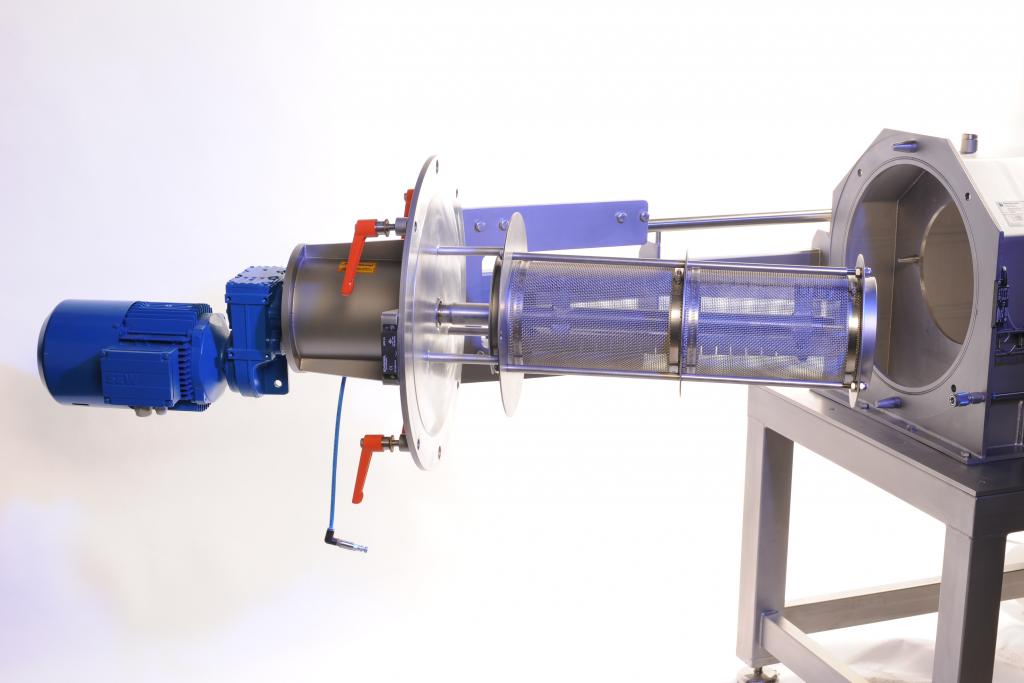

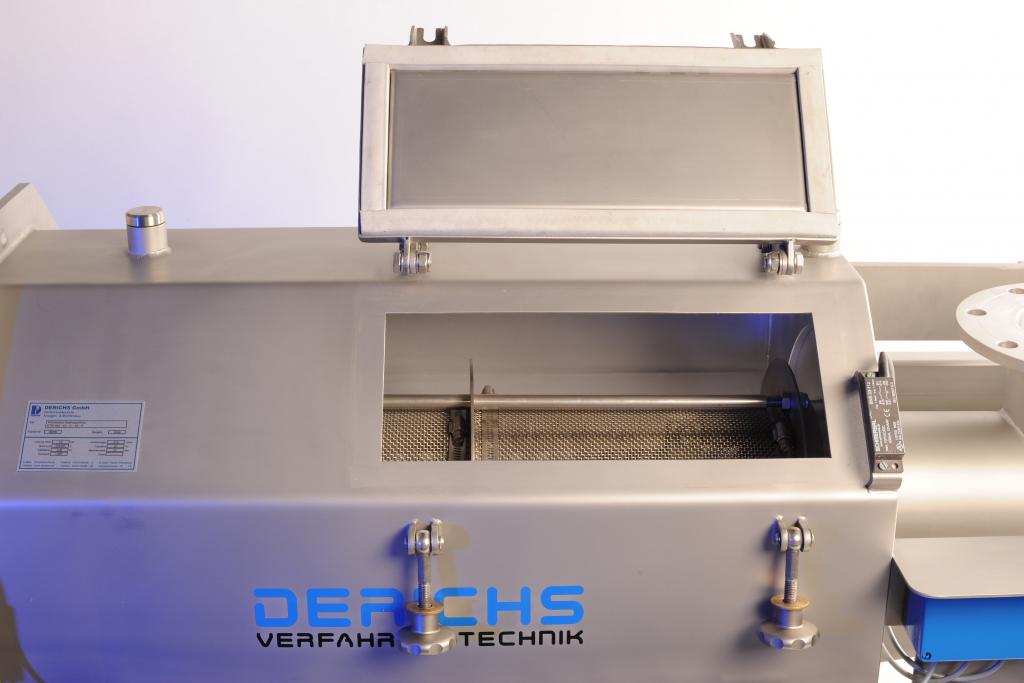

The screen basket can be simply pulled out and cleaned or replaced by a screen basket with a different mesh width after opening the quick-release fasteners. For a faster cleaning the screen machine can also be equipped with a pull-out and pivoting device on the rotor. In this version, the rotor shaft can be pulled out and swung away completely.

Different mesh sizes regarding screen fabric, plastic or stainless steel guarantee the best production results. To prevent product leakage, the shaft bearings are equipped with sealing rings and additional air purge.

- High capacity and low installation height

- Screen basket mesh width from 500 ?m to 6 mm

- Easy to clean

- Integrated feeding screw

- Screen fabric made of plastic or stainless steel

- Modular construction

- Pull-out and swinging device for screen basket

- Feeding screw with pull-out and pivoting device (without independent drive)

- Inspection openings

- Discharge hopper