Compact Filters for Dust Collectors

The Central Filter TFZ is used for the dedusting of bulk material systems, such as filling and emptying systems for bags, big bags and trucks or silo vehicles. The integrated, pneumatically cleaned pocket filter allows the use of the central filter even with hygroscopic and baking powders or granules.

The Central Filter TFZ is available with filters from 6 m² to 20 m² for air volumes of up to 40 m³ / min. The separated filter dust is collected in a dust collecting container, which must be emptied periodically. Optionally the central filter can be delivered instead of dust collector with discharge sluice and filling system for bags or big bags.

In order to generate the necessary vacuum in the filter housing, a fan can be installed on the side. A wide range of fans with different performances is available. However, if the clean air is not blown out through a connected pipeline system, but back into the work area, we recommend using a directly installed silencer to reduce the sound level.

The control voltage for the filter cleaning valves is 24V / DC. These valves can either be controlled directly by the system control or by an optional filter control unit. Compressed air with a pressure of 5 to 7 bar is required for filter cleaning.

- Advantages will follow soon

- Options will follow soon

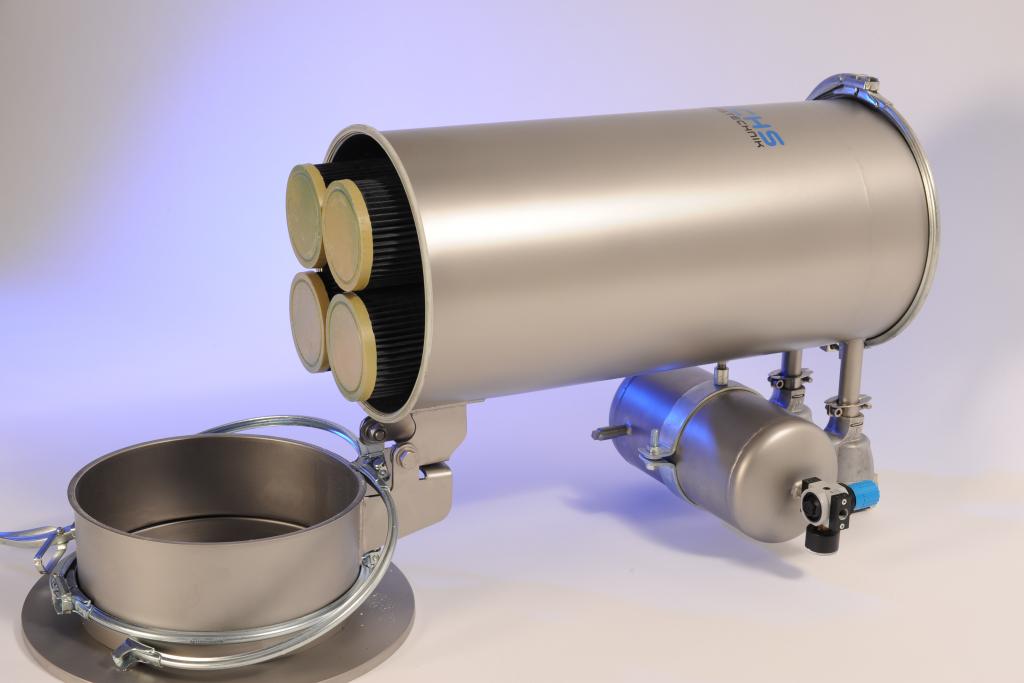

Compact and Economical Filter for Small Air Volumes

The compact filter TFP is specially developed for the dust-free ventilation and venting of containers, which are not filled by a pneumatic conveying. When using filter cartridges, the filter area is 4 m². This is sufficient for these applications because the amount of air to be dedusted is usually max. 2 m³ / min.

An integrated pneumatic filter cleaning ensures that the filter cartridges do not clog.

Two solenoid valves for the cleaning of the four filter elements can optionally be controlled by an optional filter control unit or directly by two PLC outputs with coupling relays. The power consumption of the solenoid valves is 20W at 24V-DC.

To change the filter elements, the entire filter is swung open on the raw-gas side. For this purpose, a hinge and a clamping ring connection, which can be released, are located at the bottom of the raw gas chamber.

Application examples for the compact filter are the ventilation and ventilation of:

- Mobile container

- Lock intake tanks

- Buffer tanks

- Stainless steel design

- Affordable

- Compact design

- Easy raw filter replacement

- ATEX Version

- Reed-mounted fan

- Filter control unit