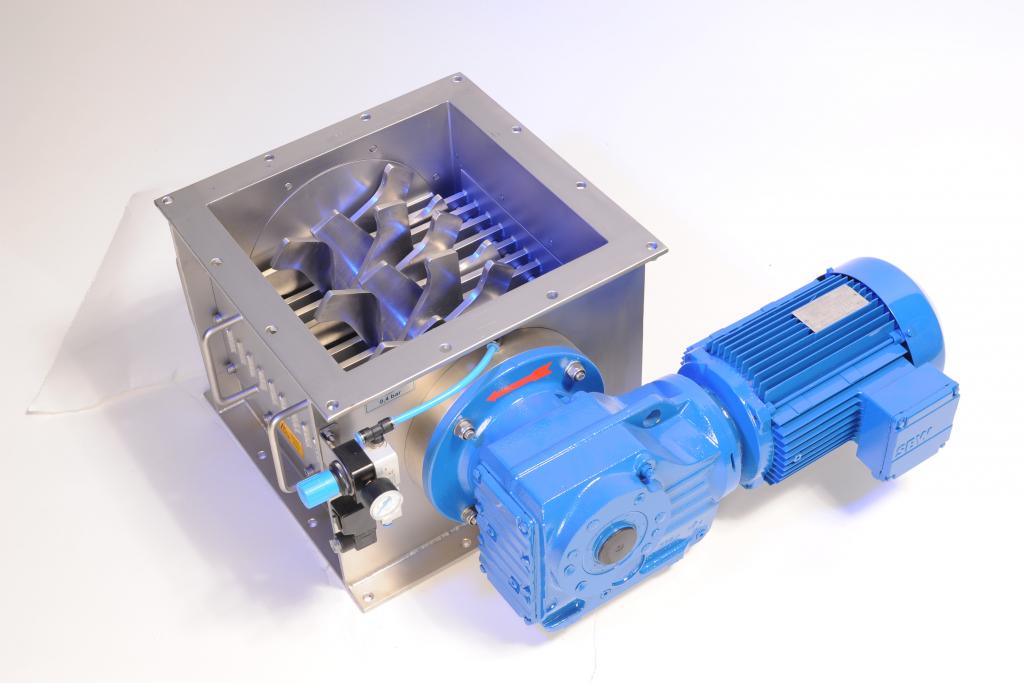

Breaking Product Lumps

The Lump Breaker ZBK is particularly suitable for the coarse crushing of product clumps. Lumps with edge lengths of up to 150 mm can be comminuted and the comminuted product having a grain size of max. 10 -15 mm.

To further comminute soft lumps or agglomerates, it is recommended to use our screen breaker or our centrifugal sifter, which can be connected downstream of the lump breaker.

Application examples for the lump breaker are:

- The comminution of clumping at the discharge of a filter unit

- Pre-comminution of frozen herbal mixtures

- Dissolving agglomerates after a bag or big-bag emptying station

- The comminution of pressed washbins, which are to be returned to the production process

- The dissolution of bonded resin granules before further processing

The breaking tool is arranged on a rotating drive and meshes with two fixed striking bars which are located at the housing doors. For maintenance or cleaning purposes these doors can be unscrewed.

Due to the largely free of dead space construction with double sealing – optionally in stainless steel – the use of the device is also possible in the food area.

The material feed should be adapted to the characteristics of the respective product.

- Robust construction

- Low installation height

- Easy to clean

- Material / hygienic design

- Shaft seal with air purge

- Breaking tools made of hardened steel

- Gear motor for frequency converter operation

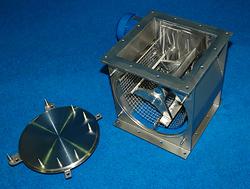

Breaking Agglomerates and Product Clumps

The Screen Breaker ZBS is particularly suitable for comminution of product agglomerates and clumps. The final grain size is thereby determined by the mesh width of the rapidly interchangeable sieves and the rotor speed. Sieve inserts with mesh widths of 2 to 15 mm are available. Due to the integrated screen effect, the downstream of an additional screen is usually not required.

Functional principle: The beaters, which are located on the rotating shaft, push the product very carefully through the screen due to its rotating movement and shape. The optional grinding gap adjustment can additionally influence the grinding result.

Application examples for the screen breaker are:

- After emptying bags and big bags

- Before entering a pneumatic conveyor

- After a belt and roller dryer

- After a mixer with liquid inlet

- Before filling bags or big bags

- Produces little fines

- No heating of the product

- Minimal energy consumption

- Compact design

- Low rotor speed

- Defined max. grain size

- Material / hygienic design

- ATEX Version

- Frequency converter

- Quick cleanable design

- Storage air purge

- Grinding gap adjustment