Diverter for Distributing and Collecting Product Flows in Pneumatic Conveying Lines

The Feeder Diverter FPW is used to distribute and collect product flows in pneumatic conveying lines. The compact construction enables an easy installation in the pneumatic conveying lines.

An optimal seal and an unobstructed conveying cross-section guarantee a problem-free use with powders and granules. The Feeder Diverter FPW consists of a housing with two side covers and an integrated drive, in which a plug with two passages directs the product stream. The housing and the plug are made of cast aluminum, but with inserts made of stainless steel (1.4541) for the product-contacting surfaces. A special sealing ring inserted into the housing serves as a seal between the housing and the rotating chuck. The outlets of the switch are pressure-resistant and gas-tight to 4 bar overpressure and pressure-resistant up to 10 bar. The drive integrated in one side cover can be installed both on the right and left.

By loosening the screws of the side cover, removing the cover and pulling out the plug, the conveyor can be disassembled quickly for cleaning purposes. However, the unit is not CIP-capable.

The feeder diverter is equipped with a pulse solenoid valve with two coils and two inductive proximity switches for the position feedback. The unit is completely wired up to the terminal box. The control voltage is 24V / DC and the required control pressure is 4 to 8 bar. The maximum permissible product temperature is 120 ° C.

- Compact design

- Easy to maintain

- No external drive parts

- Dust-tight (only in the non-controlled direction)

- Product-contacting surfaces made of stainless steel

- Gas tight to 4 bar

- EEx Version

- Control voltage 220V AC

Safe and Product-Friendly Conveying of Powders and Granules

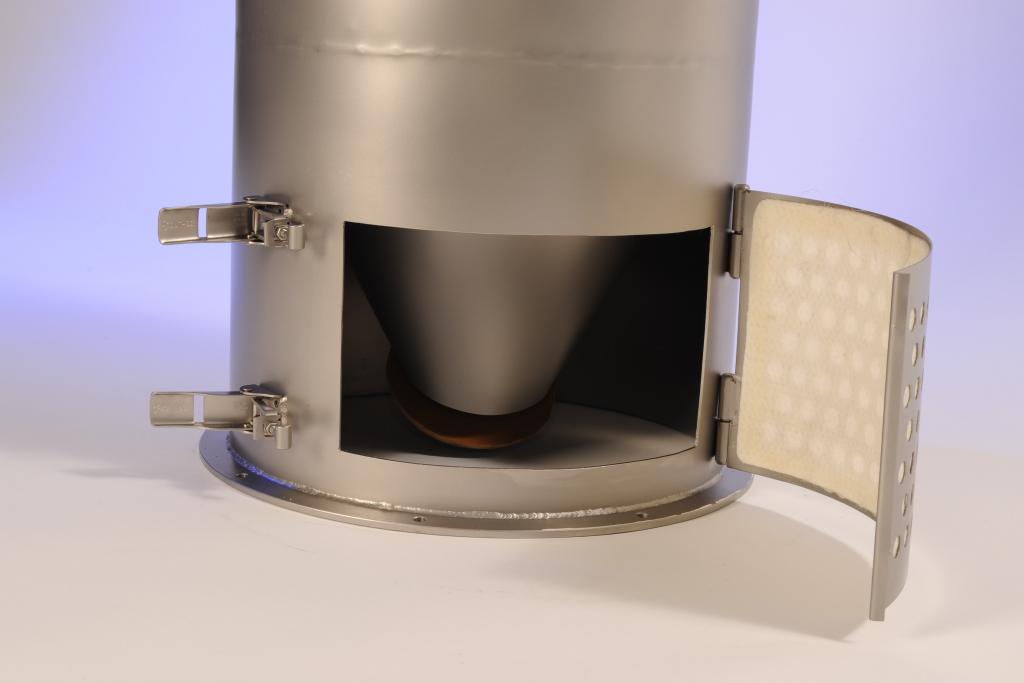

The Vacuum Conveying Unit FPS 500 is used for discontinuous, pneumatic conveying of powders and granules in the food, plastics and chemical industries. Due to the compact design, the vacuum conveyor is particularly suitable for the feeding of e.g. crushing machines, filling machines, extruders and dosing devices. The product feeding could be done e.g. from a silo, a big-bag emptying station or a bag-loading booth.

The Vacuum Conveyor FPS 500 is equipped with a passive outlet flap, which opens automatically when the device is filled and the vacuum is interrupted. Even in cases where conventional equipment fails, the specially developed pneumatically cleaned cartridge filter with a 4.2 m² filter area enables the reliable conveyance of powders and granules. Due to the swiveling lid, the filter cartridge can be easily replaced without loosening tools and screws.

The vacuum conveyor is available in steel, or in stainless steel. The control can be carried out by a central control unit or by a compact control unit which is installed directly on the suction conveyor.

An optional vacuum blower generates a vacuum. With this vacuum the product is conveyed from the delivery point into the vacuum conveyor. After an adjustable delivery time, the fan is switched off by the optional control. The outlet valve opens after the vacuum has been reduced and the product flows out. A new conveyor cycle begins e.g. by the request from downstream equipment like a level indicator. Alternatively, the request can be made by the inductive proximity switch of the outlet flap. The cartridge filter is automatically cleaned by a compressed air pulse after each conveyor cycle.

- Robust housing in welded design

- Compact design

- Integrated passive spill valve

- Easy filter replacement

- Vacuum blower

- Delivery line system

- Vacuum valve for complete emptying of the delivery line

- Changeover valve for emptying the vacuum conveyor without switching off the blower

- Integrated control

- Product feeding from silo, big-bag emptying station or a bag-loading booth or any other container

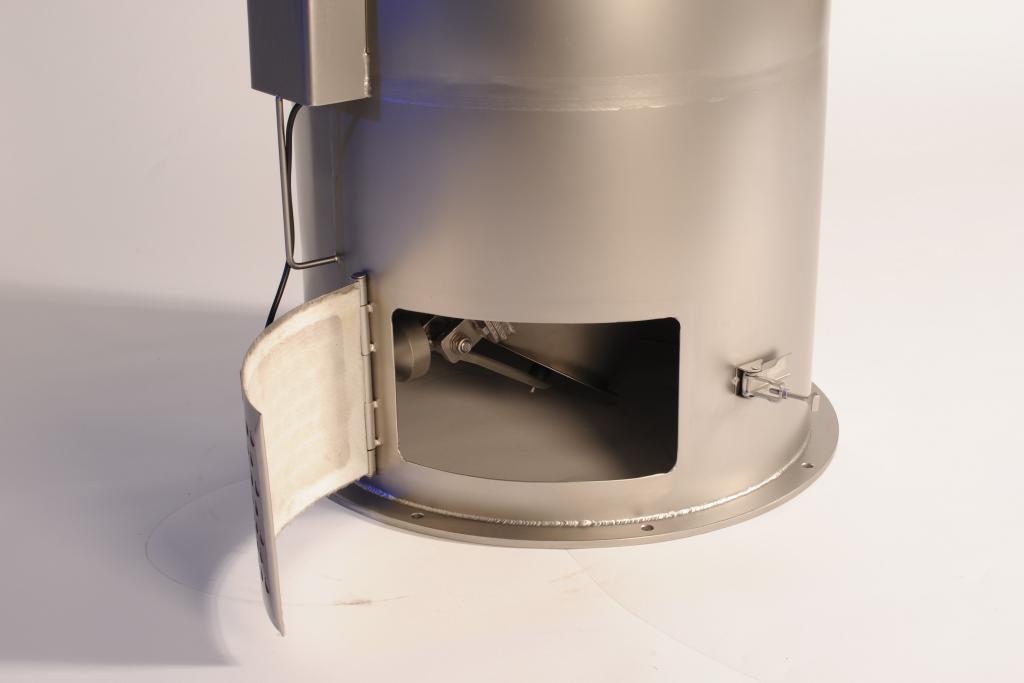

Safe and Product-Friendly Conveying of Powders and Granules

The Vacuum Conveying Unit FPS 500 is used for discontinuous, pneumatic conveying of powders and granules in the food, plastics and chemical industries. Due to the compact design, the vacuum conveyor is particularly suitable for the feeding of e.g. crushing machines, filling machines, extruders and dosing devices. The product feeding could be done e.g. from a silo, a big-bag emptying station or a bag-loading booth.

The Vacuum Conveyor FPS 350 is equipped with a passive outlet flap, which opens automatically when the device is filled and the vacuum is interrupted.Even in cases where conventional equipment fails, the specially developed pneumatically cleaned cartridge filter with a 2 m² filter area enables the reliable conveyance of powders and granules. Due to the swiveling lid, the filter cartridge can be easily replaced without loosening tools and screws.

The vacuum conveyor is available stainless steel (1.4301 or 1.4571). The control can be carried out by a central control unit or by a compact control unit which is installed directly on the suction conveyor.

An optional vacuum blower generates a vacuum. With this vacuum the product is conveyed from the delivery point into the vacuum conveyor. After an adjustable delivery time, the fan is switched off by the optional control. The outlet valve opens after the vacuum has been reduced and the product flows out. A new conveyor cycle begins e.g. by the request from downstream equipment like a level indicator. Alternatively, the request can be made by the inductive proximity switch of the outlet flap. The cartridge filter is automatically cleaned by a compressed air pulse after each conveyor cycle.

- Robust housing in welded design

- Compact design

- Integrated passive spill valve

- Easy filter replacement

- Vacuum blower

- Delivery line system

- Vacuum valve for complete emptying of the delivery line

- Changeover valve for emptying the vacuum conveyor without switching off the blower

- Integrated control

- Product feeding from silo, big-bag emptying station or a bag-loading booth or any other container

Product-Friendly and Low-Mix Conveying over Long Distances

The Dense Phase Conveying System FPD is used for conveying bulk materials over distances of up to 200 m. Due to the low conveying speed, the system operates very product-friendly. Even the most difficult products can be conveyed safely and segregated. The delivery capacity depends on the product, the pipe diameter, and the conveyor distance and is up to 10 t / h. Due to the fluidization bottom installed in the sender, even the most difficult bulk material can be conveyed.

Functional principle:

At the beginning of a delivery cycle, the product is filled into the sender and the inlet valve is closed. By injecting compressed air the pressure rises to the pre-set value at which the discharge valve opened. By pulsed injection of the conveying air in the delivery line, directly behind the outlet valve, product plugs are formed, which are conveyed at a low speed towards the receiving container. After the sender is emptied and vented, the inlet valve is opened and a new delivery cycle can begin.

If a continuous conveying of the product is needed, two senders of the Dense phase Conveying System FPD are placed side by side. The filling and emptying of these two senders takes place alternately: while the one sender is filled, the other is emptied. Depending on the product and the conveyor distance, it is necessary to inject air into the delivery line at several points in order to divide long conveying plugs and thereby prevent clogging.

- Product-friendly conveying

- Low conveying speed

- Conveying distance up to 200 m

- Conveying also of difficult products

- Low-Mixing Conveying

- Low conveying air consumption

- Built-in fluidization

- Closed System

- Design with two sender for continuous conveying

- Injection nozzles for injection of the secondary conveying air

- Compressor with compressed air preparation

- System control