Safe and Product-Friendly Conveying of Powders and Granules

The Vacuum Conveying Unit FPS 500 is used for discontinuous, pneumatic conveying of powders and granules in the food, plastics and chemical industries. Due to the compact design, the vacuum conveyor is particularly suitable for the feeding of e.g. crushing machines, filling machines, extruders and dosing devices. The product feeding could be done e.g. from a silo, a big-bag emptying station or a bag-loading booth.

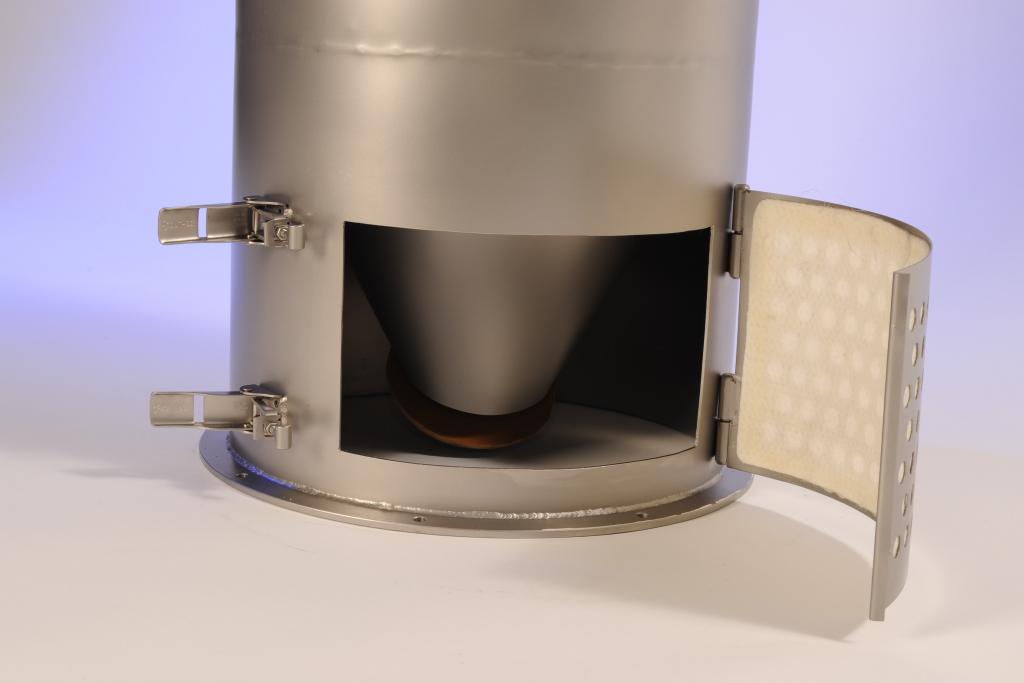

The Vacuum Conveyor FPS 350 is equipped with a passive outlet flap, which opens automatically when the device is filled and the vacuum is interrupted.Even in cases where conventional equipment fails, the specially developed pneumatically cleaned cartridge filter with a 2 m² filter area enables the reliable conveyance of powders and granules. Due to the swiveling lid, the filter cartridge can be easily replaced without loosening tools and screws.

The vacuum conveyor is available stainless steel (1.4301 or 1.4571). The control can be carried out by a central control unit or by a compact control unit which is installed directly on the suction conveyor.

An optional vacuum blower generates a vacuum. With this vacuum the product is conveyed from the delivery point into the vacuum conveyor. After an adjustable delivery time, the fan is switched off by the optional control. The outlet valve opens after the vacuum has been reduced and the product flows out. A new conveyor cycle begins e.g. by the request from downstream equipment like a level indicator. Alternatively, the request can be made by the inductive proximity switch of the outlet flap. The cartridge filter is automatically cleaned by a compressed air pulse after each conveyor cycle.

- Robust housing in welded design

- Compact design

- Integrated passive spill valve

- Easy filter replacement

- Vacuum blower

- Delivery line system

- Vacuum valve for complete emptying of the delivery line

- Changeover valve for emptying the vacuum conveyor without switching off the blower

- Integrated control

- Product feeding from silo, big-bag emptying station or a bag-loading booth or any other container