Conveying and Dosing of Various Bulk Materials

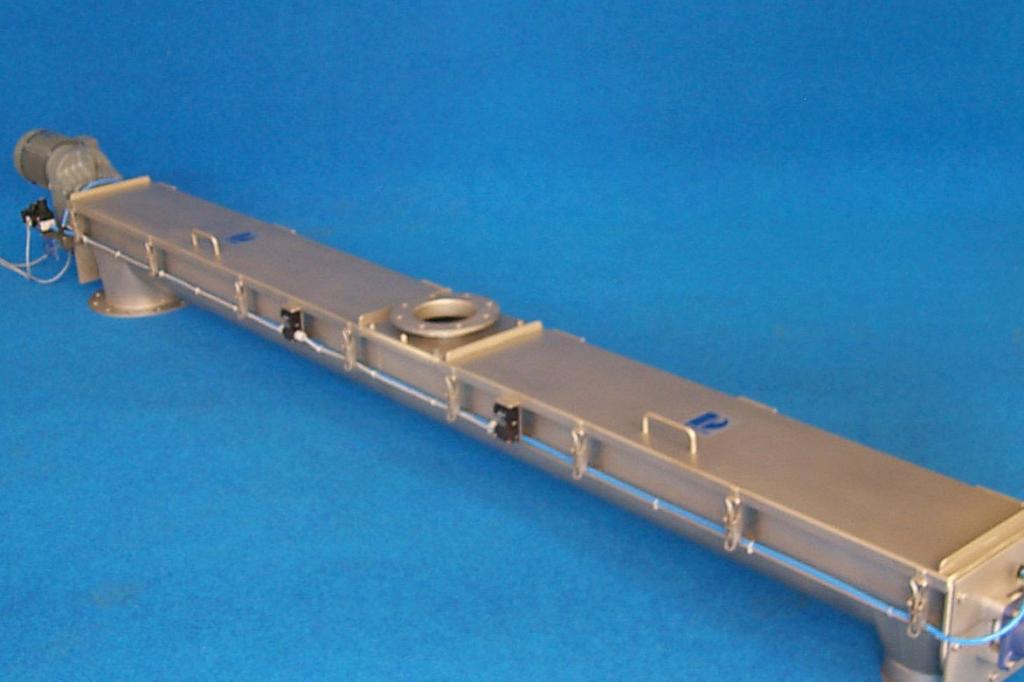

Screw conveyors are used to dispense or promote products horizontally up to approx. 7 m or vertically up to 3 m. Depending on the application area either tubular screw conveyors or trough screw conveyors are used. The advantage of the trough screw conveyors is that the trough covers can be opened in the case of cleaning.

In order to clean the troughs quickly, the trough covers can be optionally equipped with hinges and quick-release fasteners.

Screw conveyors can be used for almost all bulk materials in the food industry, chemicals and pharmacy. The screw diameters vary between 100 and 400 mm, depending on the conveyor length and delivery capacity.

Functional principle:

The bulk material is given into the conveyor through the inlet. There it is conveyed by the screw spirals to the outlet. In the case of dosing and weighing processes, the drive is generally controlled by a frequency converter in order to achieve a coarse and finest flow, which allows a weight-accurate dosing. In order to prevent product trickling at the outlet an optional pneumatically operated outlet flap can be installed.

Although the conveyor length as well as the number, dimension, and position of the inlets and outlets are manufactured according to the customer, we use standardized components such as bearings, shaft seals, drives, troughs and screw tubes.

- Affordable

- Inside inspection of the screw conveyor possible

- Up to two Outlets

- Multiple Inlets

- Stainless steel design

- Food Finish

- ATEX Version

- Shaft seal by air purge

- Troughs with hinges in the trough covers

- Troughs with quick-release fasteners on the trough covers