Dosed Transferring and Feeding of Free-Flowing Products

The Dosage Valve DSZ is particularly suitable for dosed transfer of bulk goods. For example, it can be used as a metering element for a big-bag filling or as a feeding element in a screening machine or a vacuum conveyor.

Due to the gap dimensions and production tolerances, it is not intended as a substitute for a classic discharge or rotary valve, but as a cost-effective alternative for simple tasks.

Application examples for the dosage valve are:

- Metering element over a big-bag filling

- Flow brake for products after a longer down pipe

- Metered discharge from a silo

- Metered filling of product into a pneumatic conveyor

- Metered product feeding onto a screen or metal detector

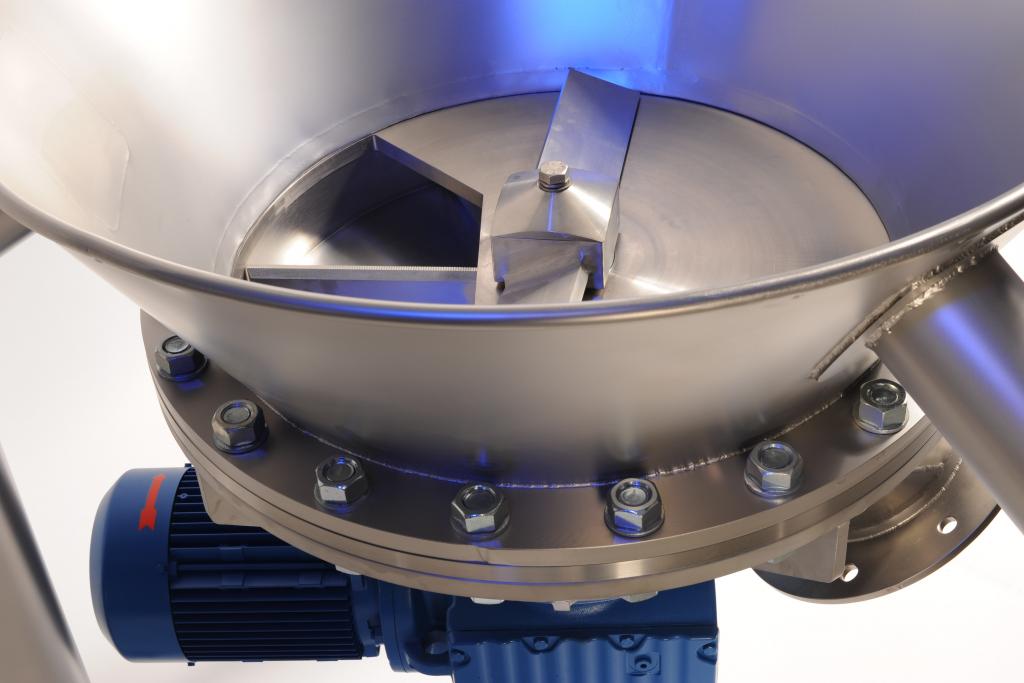

Optionally, the Dosage Valve DSZ can be equipped with a pull-out device. This allows removing the valve windows quickly and easily from the housing for inspection and cleaning purposes.

A pivoting device provides optimum accessibility.

Due to the free of dead space construction with double sealing, also optionally in stainless steel, the use of the device is also possible in the food industry

- Robust construction

- Low installation height

- Easy to clean

- Material / Hygenic design

- Shaft seal with air purge

- Extraction device for fast cleaning

- Gear motor for frequency converted operation

Teilen auf ...

Safe Discharge and Dosing of Bulk Goods, ATEX Approved Protection System

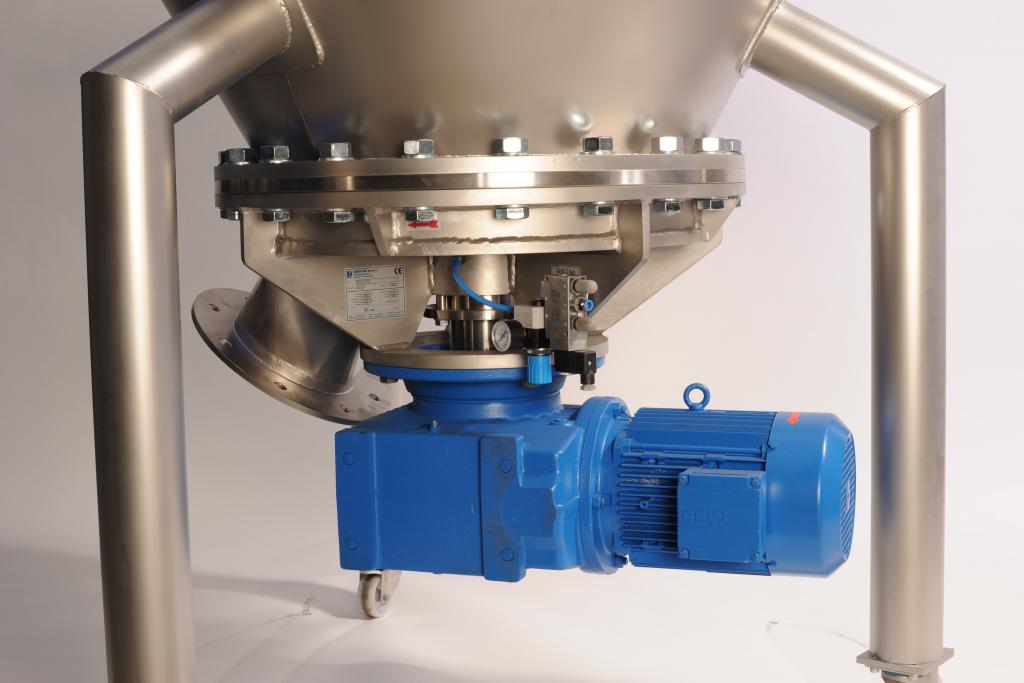

The Rotary Valve DSR combines the characteristics of a stirrer with those of a discharge lock. This makes it possible to discharge even very small powder and granules from a container or silo and to feed them directly into a pneumatic conveyor.

Due to the large inlet cross-section of the Rotary Valve DSR and the into the container projecting stirrer, bridging can be prevented in most cases. Depending on the type, the discharge capacity of the stirrer lock is up to 19,000 liters / h at 70% degree of filling.

The Rotary Valve DSR is directly installed on the outlet flange of the tank or silo. The drive is operated by a worm gear, wherein the dosing power can be continuously regulated when a frequency converter is used.

The shaft seal is optionally made of a stuffing box or a sealing ring with air purge.

The rotary valve has been certified for use as an explosion barrier. Derichs applies a QM system with the necessary qualifications for the production of such systems.

The Rotary Valve DSR is available in both steel and stainless steel.

For applications with high hygienic requirements, we have developed the rotary valve in a quick-dismountable version.

- Safe discharge of viscous bulk goods

- Direct feeding into pneumatic conveying

- Compact design – low installation height

- One drive for the lock and stirrer

- Material / Hygenic design

- Frequency converter

- Feeding shoe for pneumatic conveying

- ATEX Version

- Pressure and flame resistant